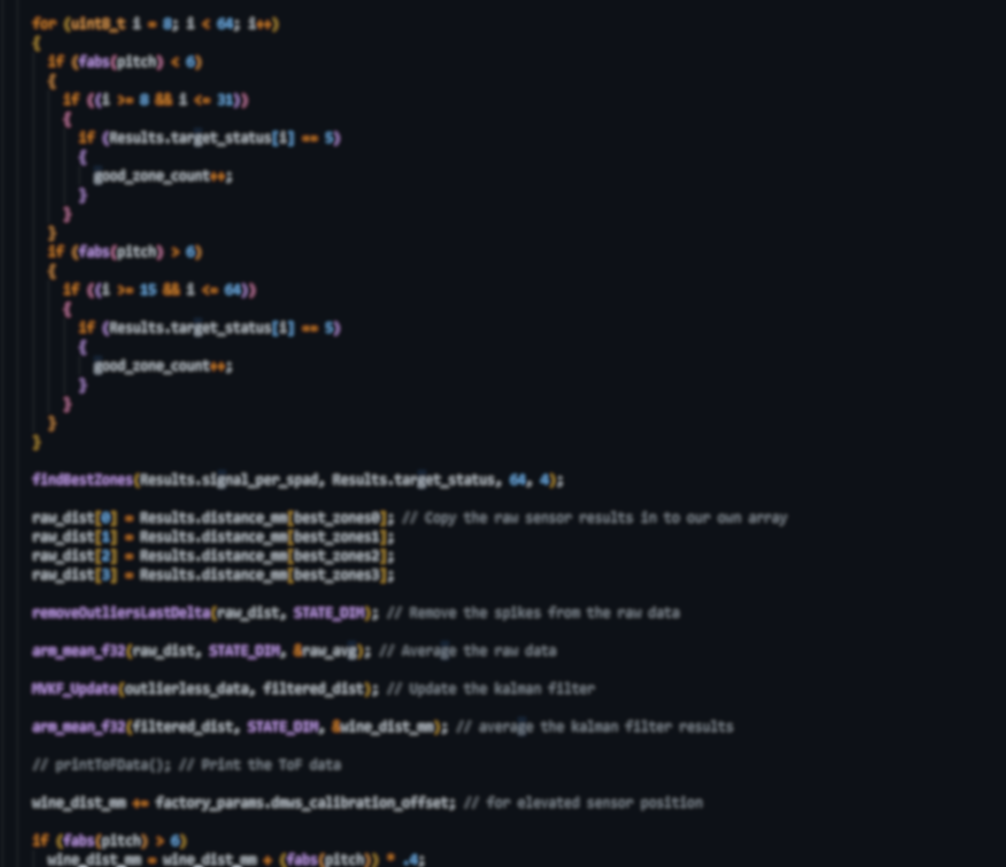

Barrel Monkey Topper Fill Algorithm

Developed a real-time control system for the Barrel Monkey Topper barrel top-off system. The code is written in C and controls all of the barrel filling functions of the device. The measurement algorithm takes the multi-zone distance data from a Time of Flight sensor and processes it throught a multi-variable Kalman Filter to estimate the current fill level of the barrel.The measurement algorithm was developed over several prototype iterations with different sensors and configurations before landing on using a multizone sensor and multiple stages of filtering to get a robust measurement. The algorithm also uses the tilt angle of the device to augment the data from the time of flight sensor by using the inclination of the device to correct for the tilt of the barrel when choosing which zones will be used to make the distance measurements. A calibration offset can also be applied to the measurement as well as a correction factor based on the tilt angle of the device, while the device is tilted past some threshold.

The fill machine algorithm then takes the estimated fill level measurement and controls the phases of the barrel fill process; fast fill, slow fill, wait, and others based on the measurement and the fill behaviour so far. The device always tries to fill a barrel as precisely as possible while minimizing the time, but conditions in the barrel may require that the device change the fill profile to adjust for foam in the wine or other conditions. The algorithm can insert wait times to compensate for foam in the wine, and can take multiple cycles, to allow for foam to settle and the wine to be more precisely measured. The algorithm measures the times of the fill phases so that it can adjust it's behaviour to compensate for different conditions in the barrel.

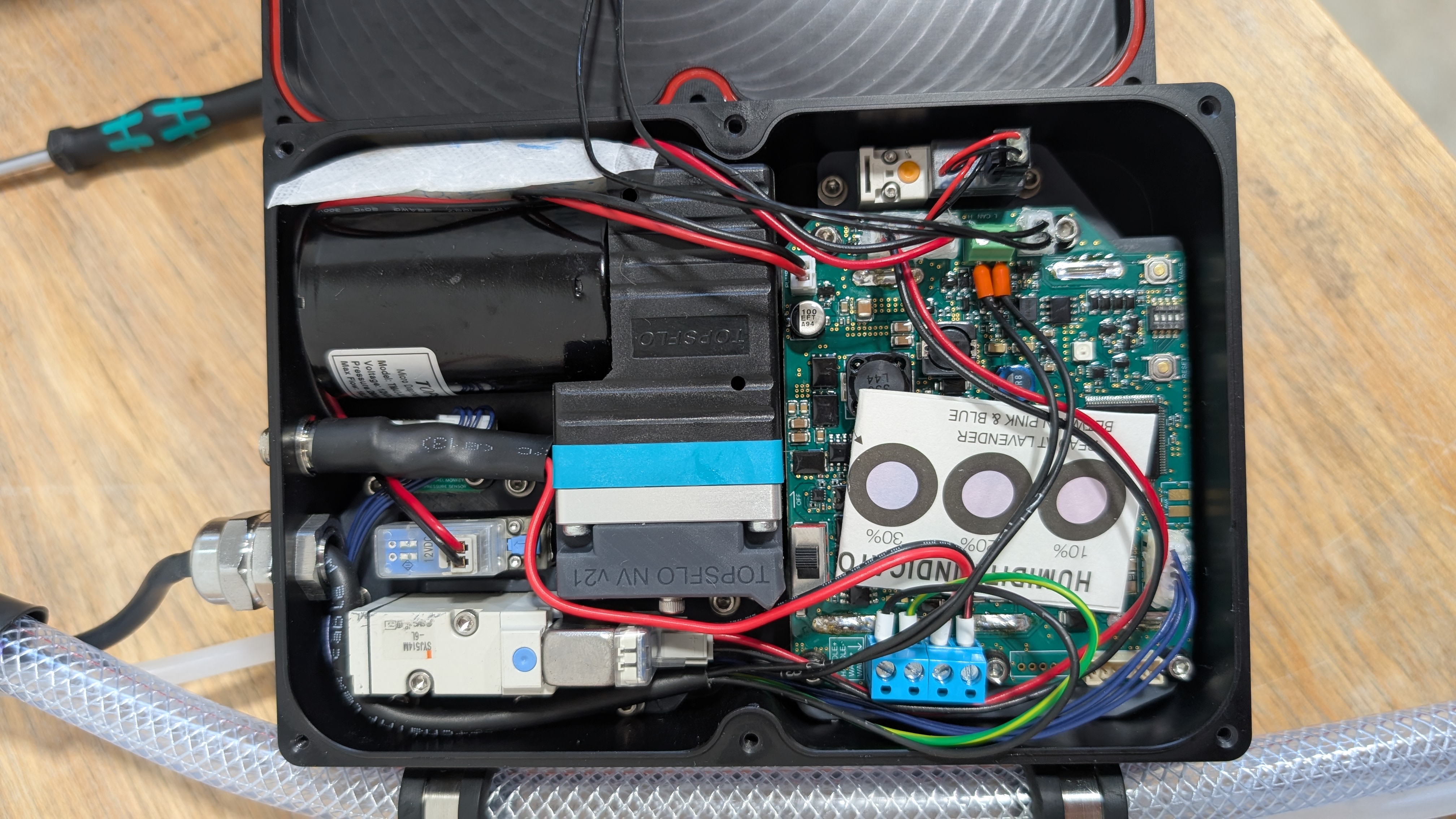

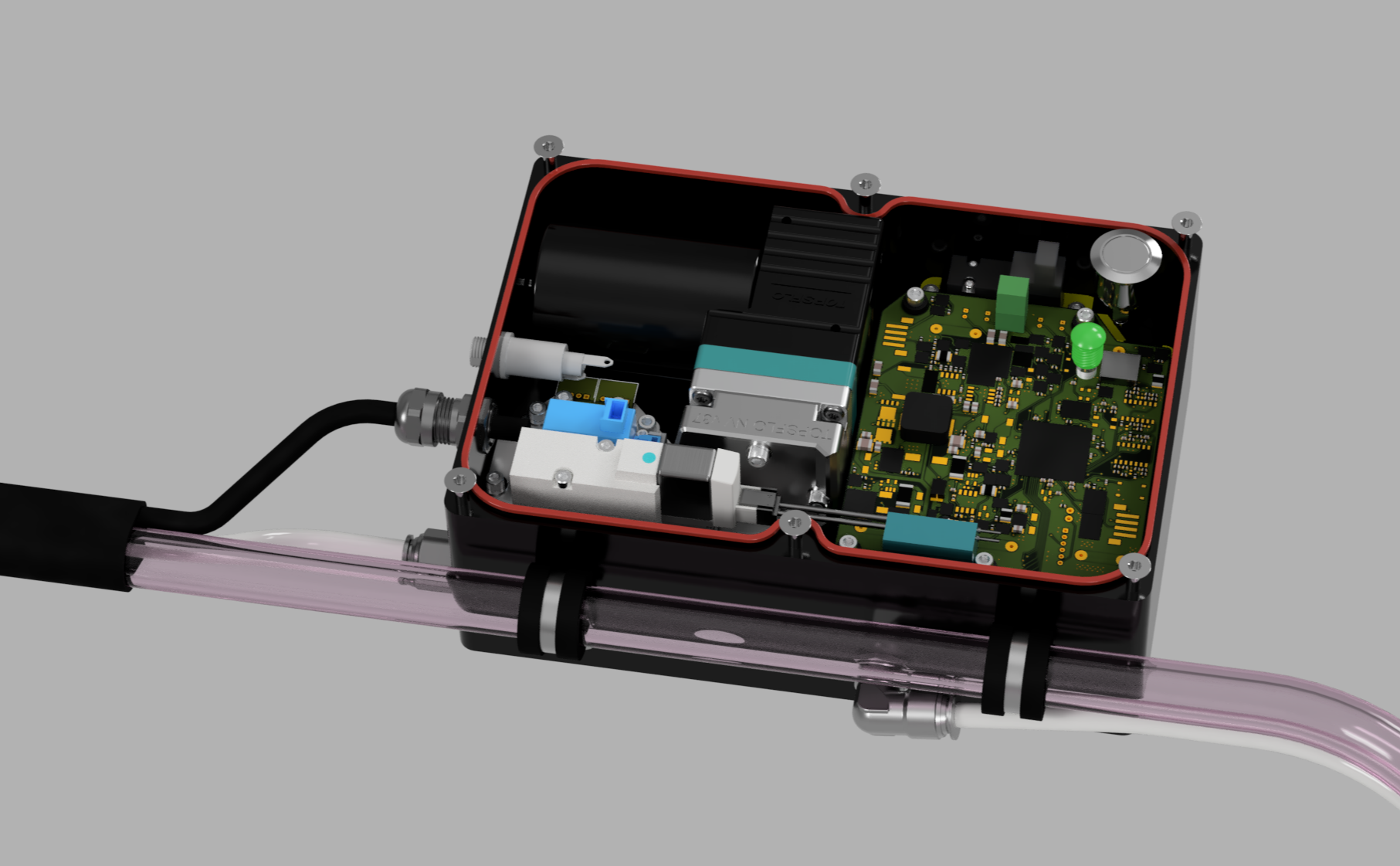

Topper Battery Enclosure Design

Designed a machined aluminum enclosure to house the battery pack and components for the Topper barrel top-off system. The enclosure integrates the battery pack, the BMS and Controller PCB, the solenoids that control the pneumatic valves, an air pump, a manifold to connect the pumps and valves, a pressure sensor, and an air reservoir. The 3D printed pump manifold allows us to package the components extremely compactly, and we have worked hard to make the enclosure as easy to use and maneuver as possible.

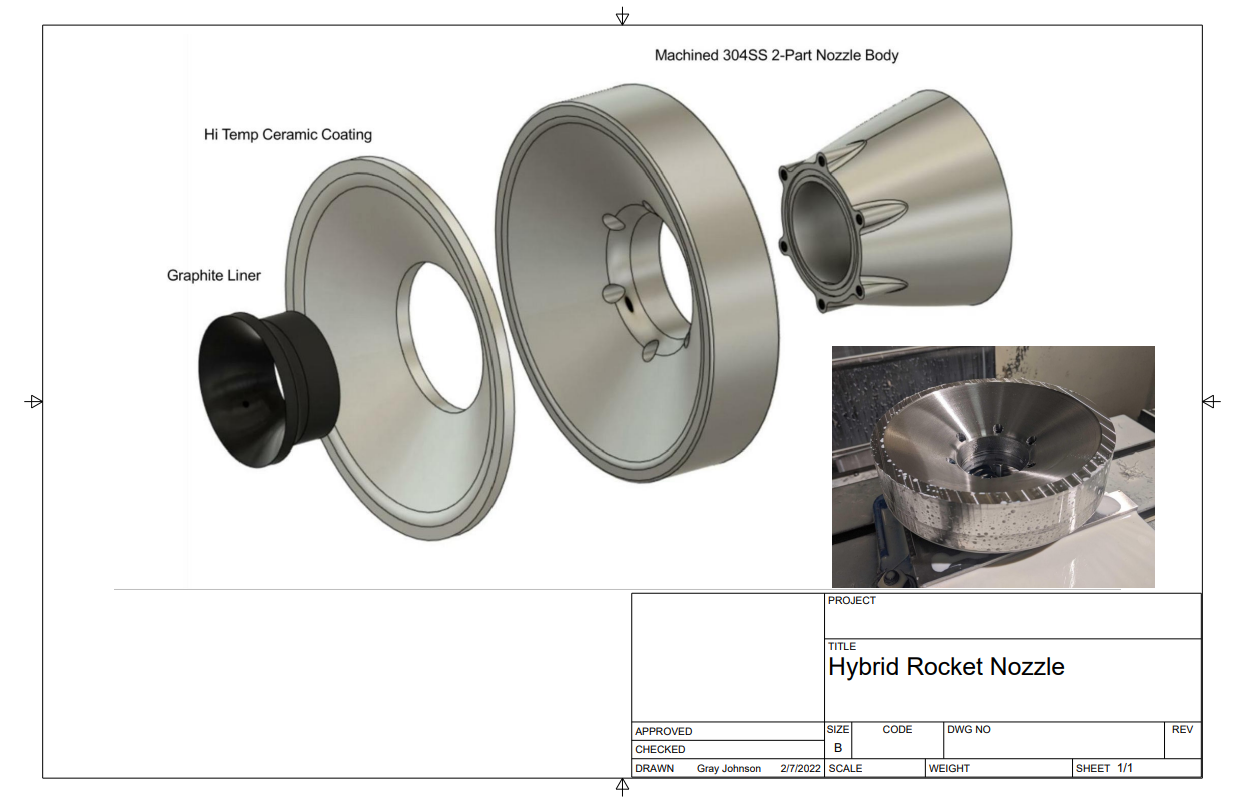

OSU Hybrid Rocket - Nozzle Design Capstone Project

Designed and prototyped a novel hybrid rocket nozzle design. The nozzle is designed to be manufactured from a stainless steel body for strength and durability, with a replaceable graphite throat section for ease of manufacturing and repair. The converging section is designed to be coated with a refractory ceramic material for high temperature performance. The graphite throat was tested in small scale tests, and the ceramic coating was applied and tested on stainless subtrates but the final design was not completed due to the COVID-19 pandemic.